What Makes a Meter a Max Precision Flow Meter?

When it comes to low flows or intermittent flows, there’s no replacement for positive displacement meters. Coriolis, ultrasonic, thermal mass, and magnetic meters have their places when flow is relatively consistent without abrupt flow profile changes. Do you need 1,000:1 turn down? Bi-Directional flow control? Fuel injector testing? Valve leak testing? When you do have need for instantaneous flow profile data and control, use the highest resolution, fastest reacting positive displacement liquid flow meter, a Max Precision Flow Meter.

Max Precision Flow Meters offer capabilities that are unique to positive displacement meters with the additional benefits of higher accuracy and higher resolution that no other meter manufacturer can do.

Why would I choose a Max flow meter for my application?

We measure your difficult applications when other meters will not meet your needs.

Max Meters can provide:

- Nearly instantaneous data output of 1.6 milliseconds

- 0.2% Accuracy of Reading over a 200:1 turn down range

- K-Factors up to 12,000 pulses/cc

- NIST traceable calibrations for all products across their full flow range up to 2000:1 turn down

- Measure flow rates as low as 0.005 cc/min

- High Accuracy and repeatability for intermittent injection streams

- Matched forward and reverse accuracy for Bi-Directional flow and null crossing measurements

- Programmable meter settings to adjust meter outputs to your application needs

All of the above features are in addition to the standard benefits of all positive displacement meters:

- No straight piping requirements – laminar flow is not needed.

- Viscosity independent over most application ranges

- Instantaneous movement with all liquid flow

What kind of Service and Support do you provide?

- We provide technical consultation for the lifetime of your Max flow meter. We are committed to providing you, our customers, with the information needed for a successful and easy installation. All you have to do is Contact Us.

- Our manufactured products are covered under our standard manufacturer’s Warranty.

- Calibrations and refurbishment of our flow meters are available on an as quoted basis. Submit the Service Request form for price and lead time.

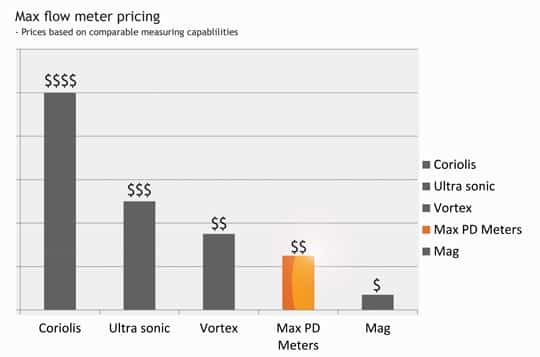

What is the Price of a Max Precision Flow Meter?

- The price of a Max Precision Flow Meter is determined by your application needs. (You wouldn’t cross shop a measuring tape with a micrometer. They are meant for different jobs. A Max meter, needs to be selected for your application needs first.) Flow range, accuracy needed, type of signal output, and need for hazardous location protection all are incorporated into determining why you will be buying a Max meter. We provide a value with our measurement capabilities that is unsurpassed when you have a need for measurement where you cannot measure another way. For specific model pricing, contact us with the information requested on the Request for Quotation.

What is a typical product lifespan for a Max meter?

- We design and manufacture our flow meters to last a long time in industrial environments. The easier the application, the longer the meter will last. The harsher the application, the more often you may need to replace equipment. On average, single use customers order from us approximately every 5-7 years and we have many meters operating for 20 years or more in various applications. We calibrate meters no matter how old they are. Our refurbishment program ends with meters that are 10 years old and older. The 10 year refurbishment span is based on the fact that the metering technology has changed greatly in that time. While a new Max meter may look like a Max meter from 35 years ago on the outside, advances in metallurgy, breakthroughs in coatings, and improvements in electronics technology make the latest Max meters a superior product to those sold last decade.

What are some of the most common applications of MAX flow meters?

- Positive displacement meters, including Max meters, thrive in low flow, intermittent flow, and variable viscosity markets.

- Fuel injector testing include all engine types:

- Aerospace – UAV and drone engines on test benches and in-flight

- Yard maintenance equipment – mowers, trimmers, blowers, chain saws

- Two wheelers – motorcycles and mopeds

- Automotive – gasoline, diesel, bio-fuels

- Heavy truck – diesel and DEF (AdBlue)

- Off highway vehicles – diesel and DEF (AdBlue)

- Chemical injection systems

- Natural gas odorant

- Reverse osmosis anti-scalant

- Oil and gas corrosion inhibitors

- Bottling line sanitation systems

- Refrigerant filling systems – industrial, aerospace, semiconductor

- Anti-freeze filling systems – industrial and automotive

- Variable/High Viscosity Materials

- Urethane mixing systems

- Conformal coatings

- Hot melt adhesives

- Silicone and silicone based products

- Asphalt and tar applications

- Reverse Flow and Leak Testing

- Aerospace hydraulic valve testing

- Aerospace component testing

- Brake testing for aerospace

- Auto/Truck brake testing

- Off-highway hydraulic valves and regulator testing

- Electric vehicle battery cooling system testing