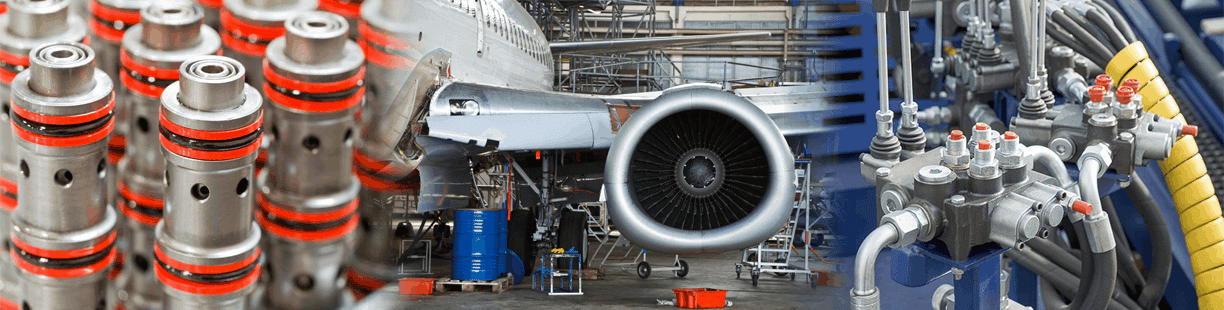

Testing of hydraulic fluid throughout an aircraft’s hydraulic pumps, motors, cylinders and actuators to operate wheel brakes, nose wheel steering, landing gear, flaps and slats, flight controls, stairs and cargo doors are all areas Max Precision Flow Meters are used. Various Test stands for valve leakage, mapping of flow profiles, and determining maximum flow rates include our products. Common fluids for these types of application are Skydrol®, Fyrque®, HyJet®, and other phosphate ester based fluids.

INDUSTRY PREFERRED TECHNOLOGY

For aviation specific hydraulic fluid testing, Max offers the following flow meters:

- P001 (LEAK TESTING)

- K-Factor: 12,000 pulses/lcc

- Flow Rate: 0.005 cc/min – 200 cc/min

- P213 (LEAK TESTING)

- K-Factor: 1000 pulses/cc

- Flow Rate: 0.5 cc/min – 1800 cc/min

- G004 (BI-DIRECTIONAL VALVE TESTING)

- K-Factor: 500 pulses/cc

- Flow Rate: 0.5 cc/min – 4 liters/min

- G015 (BI-DIRECTIONAL VALVE TESTING)

- K-Factor: 200 pulses/cc

- Flow Rate: 10 cc/min – 15 liters/min

Max Machinery products have the ability to measure any viscosity fluid without a need to adjust the meter’s K-Factor. The Max Machinery transmitter technology provides for a more robust and reliable signal, and insensitivity to vibration and flow ripple, plus prevents over reporting due to pulsations in the system. Bi-directional fluid flow measurement is available on all products.

HOW DO YOU BENEFIT?

- Broader 200:1 working range reduces the number of flow meters required

- Not affected by test stand vibration or hydraulic dither

- High pressure ratings up to 7250 psi

- Drift free, reliable K-Factors over wide viscosity ranges

- Excellent null-crossing capabilities for superior bi-directional flow accuracy

Max Precision Flow Meters provide the operator the ability to precisely test hydraulic components, fine tune flow rates, and create flow control loops within their systems.

The meters are rugged, dependable, and not affected by changes in the fluid viscosity or flow profile. Even pulsating flow streams are accurately measured.

Standard pressure ratings of 3000 psi (210 bar) and high pressure ratings of 7250 psi (500 bar) are available.

Bi-directional fluid flow measurement is available on all products.